E-newsletters Company news

To play a lead role in helping operators

- to solve complex valves and flanges maintenance and

- to repair, including those associated with nuclear and oil and gas applications

requires an understanding of emergency replacement and shutdown programmes.

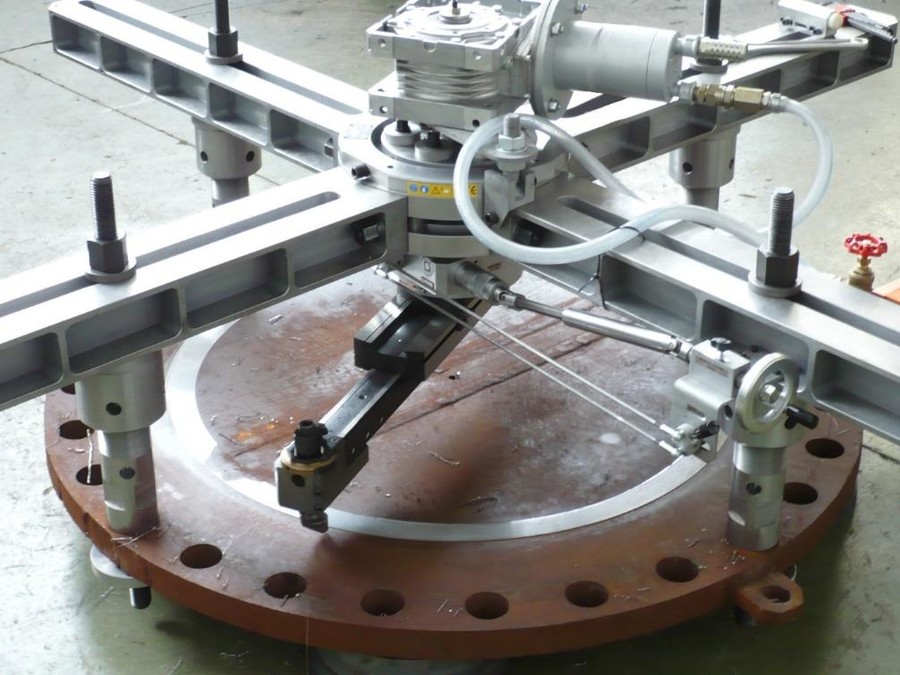

On-site machining for repair and maintenance works with the help of robust, reliable, high precise, light equipment also suited for works to be performed under tight spaces, allows to increase productivity and to decrease costs.

Traditional methods lead to:

- Time costs

- Human labor costs

- Expensiveness

- An impossibility to weld many times the components

- A potential leakage risk

World-class engineered portable machining equipment to nuclear, onshore, offshore, chemical, petrochemical, shipbuilding, prefabrication plants across the globe are available.

Portable machining equipment allow to repair components without having to replace them and therefore to cut them.

To meet the technological challenges of the coming years foundations to take research and development activities to new heights are to be laid.

There are many types of valves. However, those used in industrial and power piping applications are almost always one of the following valve types:

- Gate

- Globe

- Check

- Butterfly

- Ball

- Plug

- Diaphragm

- Etc.

In the process of performing its control function, a valve must satisfy two conditions.

- First, the fluid cannot be allowed to leak into environment.

- Second, there can be no internal leakage.

That is, when the valve is closed there can be no flow, either along the normal fluid path or between valve parts, where flow is never intended. These two conditions are not always met absolutely. Leakages, for example, are frequent and lead to high risks for the operators and environment.

We will have a look at some different kinds of valves and determine how these valves can be maintained or repaired in given cases.

In many cases, only one or two of the basic valve types are suitable for a determined use because of the valve design. Under further conditions, several types of valves are suitable and further factors such as materials may be of prime importance.

The material selected for valves will generally depend on the kind of the fluid to be carried, the operating pressure and temperature, the type of closure member and seat, and factors such as cost, weight, etc. Nuclear valves, for example, call for special steels, titanium and other exotic alloys designed especially for such cases.

Gate valves are usually used to stop flow completely.

Gate valves are used in the Nuclear or Oil and Gas industries. Many gate valves are present in all refineries across the globe.

There are two different types of gate valves:

- 2 parallel seats

- 2 conical seats

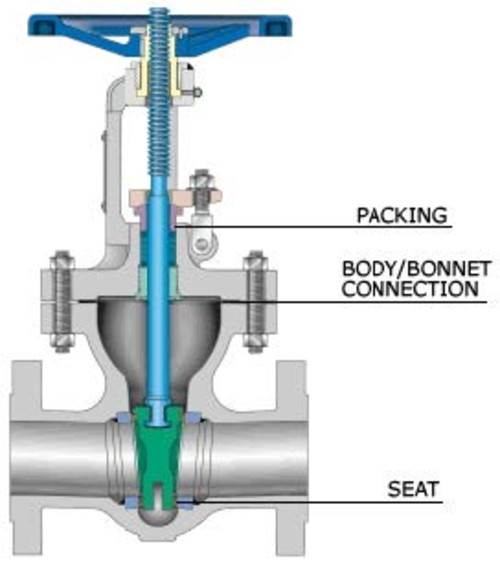

Portable machining equipment can be used to machine the body/bonnet surface or the flanges on each side.

On the largest gate valves, the machining equipment can be fixed into the inside part of the valve to repair the seats.

On gate valves, sealing surface on each side frequently needs spiral grooves.

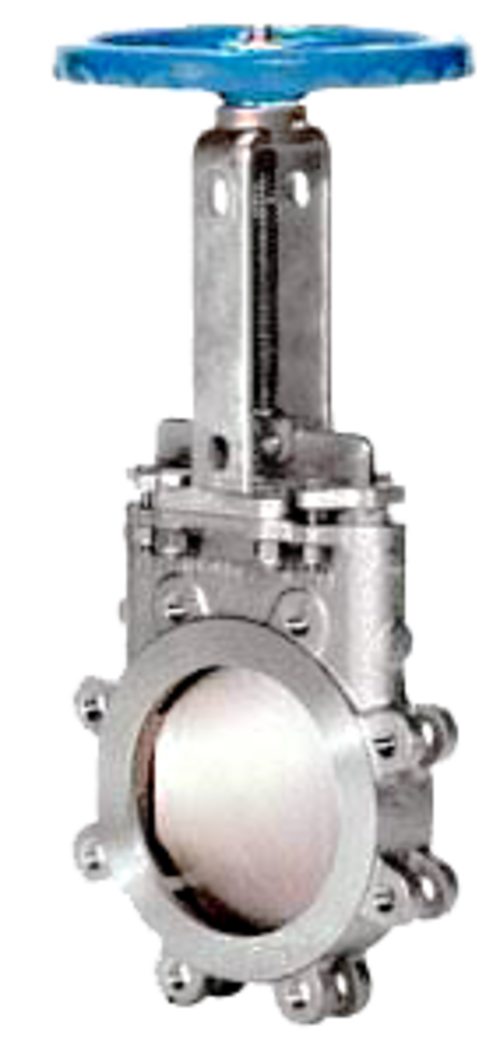

KNIFE VALVES

Knife valves are similar to gate valves, but usually more compact. Often used for slurries or powders on/off control.

Knife valves are particularly used in the refinery industry.

You need low height equipment which can be placed just between the flanges to perform facing operations.

GLOBE VALVES

Globe valves are used to regulate or throttle flow. We shall highlight where Gate valves or Globe valves are used in the industry and how their maintenance and repairs can be performed.

Globe valves machining:

- For flat seat globe valve, you will need equipment which allow to machine the sealing surface.

- For conical seat, equipment with RTJ device (axial and radial feeds combination system) is needed.

Globe valves are mostly used in the nuclear field of activity and especially the primary circuit for the contaminated flow regulation. In this case, the globe valve is directly welded in the piping network.

Some globe valves can also be found in various industries like chemical or petrochemical industries, and the valves will then be integrated into the piping network with two flanges on each side.

OTHER VALVES

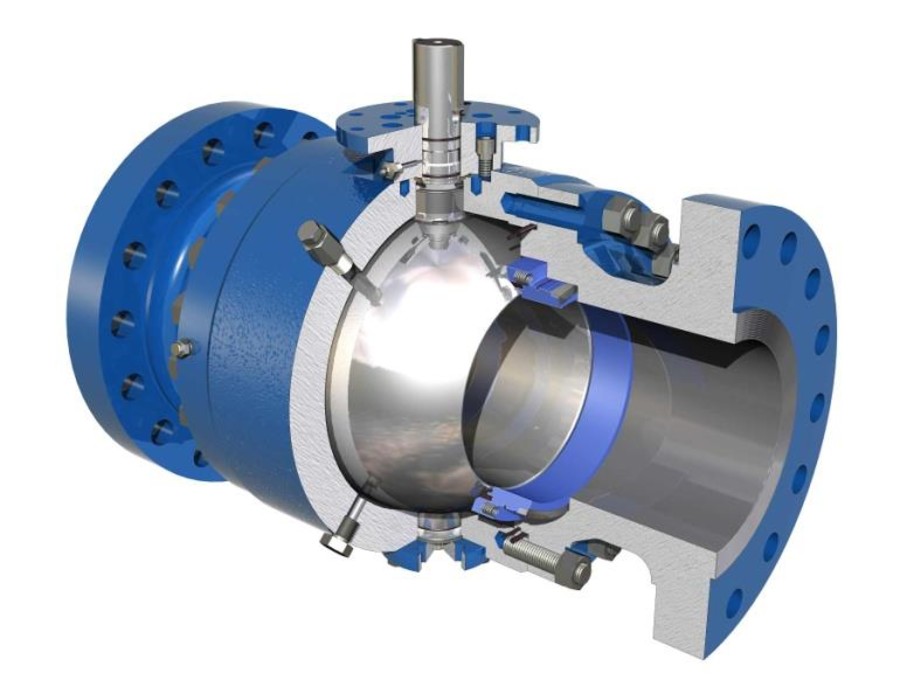

Ball valve, for on/off control without pressure drop, and ideal for quick shut-off, since a 90° turn offers complete shut-off angle, compared to multiple turns required on most manual valves. Ball valves will generally be used on a dam’s arrival of water at the end of a penstock.

Portable machining equipment will be used to machine the flanges of the valves that often need spiral grooves.

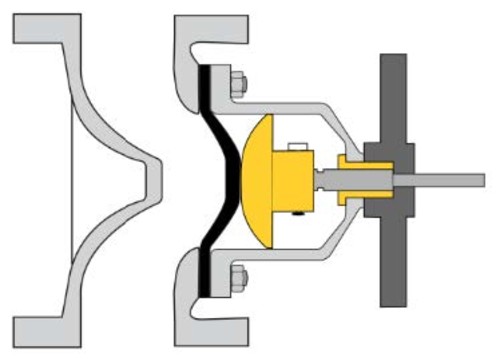

Butterfly valve, for flow regulation in large pipe diameters. Butterfly valves will be generally used on piping that bring water to power plants or dams. For the main water arrival, equipment with specific devices will be used to face the sealing surface and the surface with the hole. In the Oil and Gas industry, and especially where pipelines are laid, small butterfly valves (Ø<800mm) will be used.

Check valves or non-return valves allow the fluid to pass in one direction only. This kind of valve is frequently used in nuclear, thermal or hydraulic power plants (from DN 200mm to DN 600mm).

The seat of the valve can also be machined with a specific clamping device (with a fixing angle bracket).

The axes’ bores of the check valves have to be machined with a very high precision because the rotation axe will be adjusted.

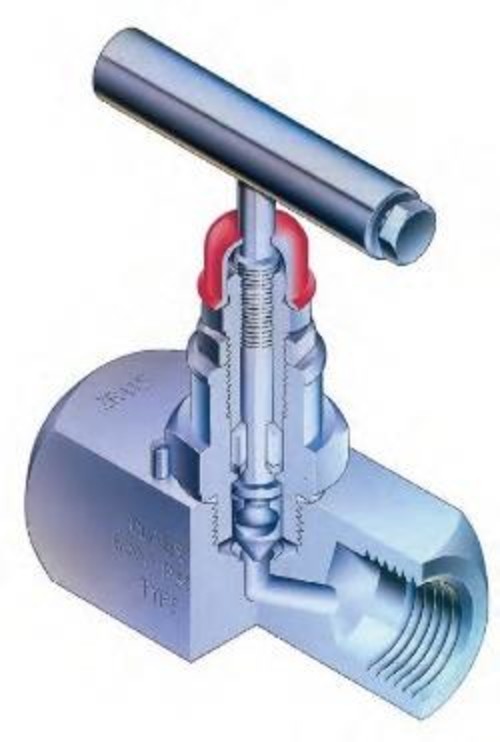

Needle valve for accurate flow control.

We can find flow control valves in a nuclear power plant.

Specifically, on the secondary circuit to regulate the turbine pressure.

Control valves are cage-guided globe valves design for this operation.

Safety valves, which are very frequently used in nuclear (thermal hydraulic power plant).

We can find them on pressure networks or close to steam generator in a nuclear power plant (VVP).

They are an important safety element in a power plant, that is why the maintenance of safety valves have to be perfectly done.

Some specific accessories for VVP valves with short columns and stronger boring arms for big depth machining (500 mm) to reach the seat of the valve can be provided.

Sometimes, conical machining is required and it is necessary to perform it with an RTJ device that will combine the axial and radial feeds.

On a flat seat we need a roughness of Ra 0.8.

Choke valves, valves that raise or lower a solid cylinder which is placed around or inside another cylinder which has holes or slots. Used for high pressure drops found in oil and gas wellheads.

This kind of high pressure valve will be found mostly in thermal power plants.

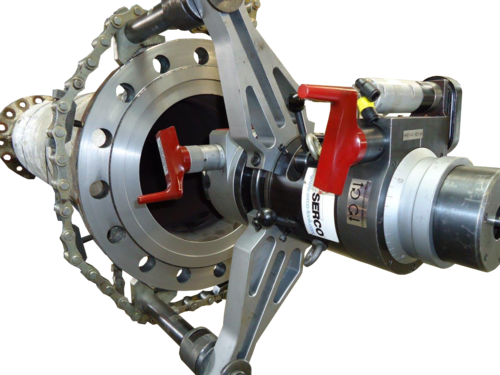

A chain clamping device can be used to clamp the machine on the OD part.

Diaphragm valves, which control flow by a movement of a diaphragm. Upstream pressure, downstream pressure, or an external source (e.g., pneumatic, hydraulic, etc.) can be used to change the position of the diaphragm.

We can find flow control valves in nuclear power plants.

Specifically on the secondary circuit to regulate the turbine pressure.

For body/bonnet and flanges, equipment associated with a chain clamping device will be used for a perfect repair.

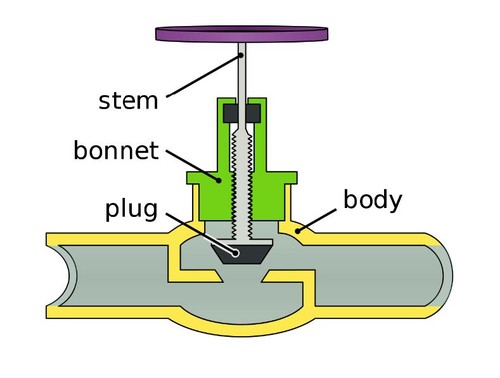

Plug valves, slim valves for on/off control but with some pressure drop.

For sensitive application, these valves can be controlled remotely.

It is more convenient to work on each side flanges of the valve with adapted equipment.

Poppet valves works as Check valves with an additional capacity which consists in allowance free flow across the seat.

Pinch valve, for slurry flow regulation.

Pinch valves are used to regulate flows that are not as liquid as water (slurry, wastewater, etc.).

This kind of valves are mostly used in purification plants, wastewater treatment plants, pumping stations etc., where it is needed to regulate flows that are not clean or with different densities.

The most common maintenance and repair cases will consist in the surfacing operation on the flanges with the help of a chain clamping device. You need a machine which is able to be set up between two flanges.

Usually, it is the flange that receives the valves which are machined but the flanges of the valve can be repair too. Streaks are often necessary on the seal surface to grip the gasket.

Which equipment are available and for which surfaces?

What equipment will help you solve your maintenance and repair works on field?

- Portable boring and surfacing machines

- Portable surfacing machines

- Portable equipment for conical machining

- Portable equipment for grinding

- Portable grooving bench

- Simple adjustment

- Safe operation

- Cold machining

- No sparks

- Accuracy

- Concentricity 0.01

- Surface finish Ra 1.6

- Time saving

- High productivity

Examples of applications:

The primary objective when using a portable facing and boring equipment for flanges and valves is to increase the service life of a flow control element by machining the parts worn by passing fluid. In this context, the machines can be used for a lot of applications. You will find below some examples which are about some above-mentioned valves:

Gate valves: Machining sealing surfaces, bolt working surfaces and valve seats (parallel or tapered seats).

Globe and Ball valves: A type of valve often used in nuclear power plants they are to be found on the primary fluid regulation circuit. You need equipment suitable for this type of valve (flat seats) which is able to machine all the sealing zones on the valve thanks to its compactness and machining capacities. For valves with tapered seats, you need equipment suitable with its combined feed system for machining conical forms.

Check valves: Machining body-to-bonnet sealing surfaces and flanges.

Butterfly valves: Flanges for holding the valve where grooves are often made for the seals. High pressure valves: Machining body-to-bonnet sealing surfaces, an excellent surface finish is often required for the valve seat, which necessitates the use of a portable machining unit.

Safety valves: Mainly positioned around steam generators or other pressure apparatus, you need a machine particularly suitable for resurfacing sealing surfaces and bolt working surfaces as well as valve seats, and notably special tooling for machining MSSS valves, the seats of which are often very deep.

Machining of the seal surface

Depth: 543 mm

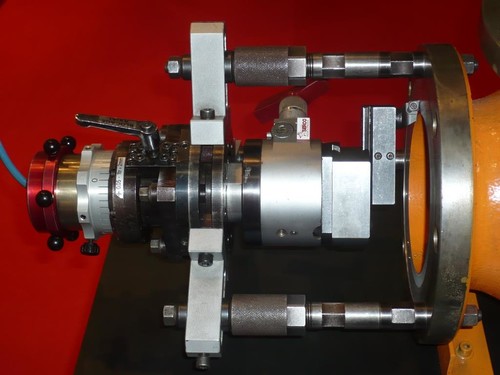

With portable machining unit, SERCO TU 400

+ specific mounting equipment

Result: Ra 1.2

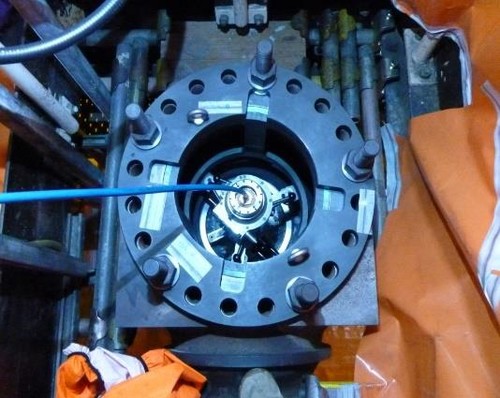

Control valves:

4 ‘’ valve on GSS circuit (Steam heater) Valve seat machining + machining of the body/bonnet surfaces

SERCO machines represent the culmination of over 50 years of technical expertise, know-how and SERCO’s understanding of the key issues of their industrial partners throughout the world. SERCO’s major advantage lies in its ability to design equipment whose component elements provide total rigidity, which, in turn, enables machining to be done with accuracy to 0.01mm. What makes SERCO machines unique and particularly adapted to on-site machining is illustrated by their ease of installation and set-up. To set-up a flange facing machine, adjustments need to be made in concentricity and parallelism. SERCO is the only manufacturer in the world capable of building equipment that enables these two set-up operations to be carried out totally independently.