Shipbuilding capability

Shipbuilding Capability

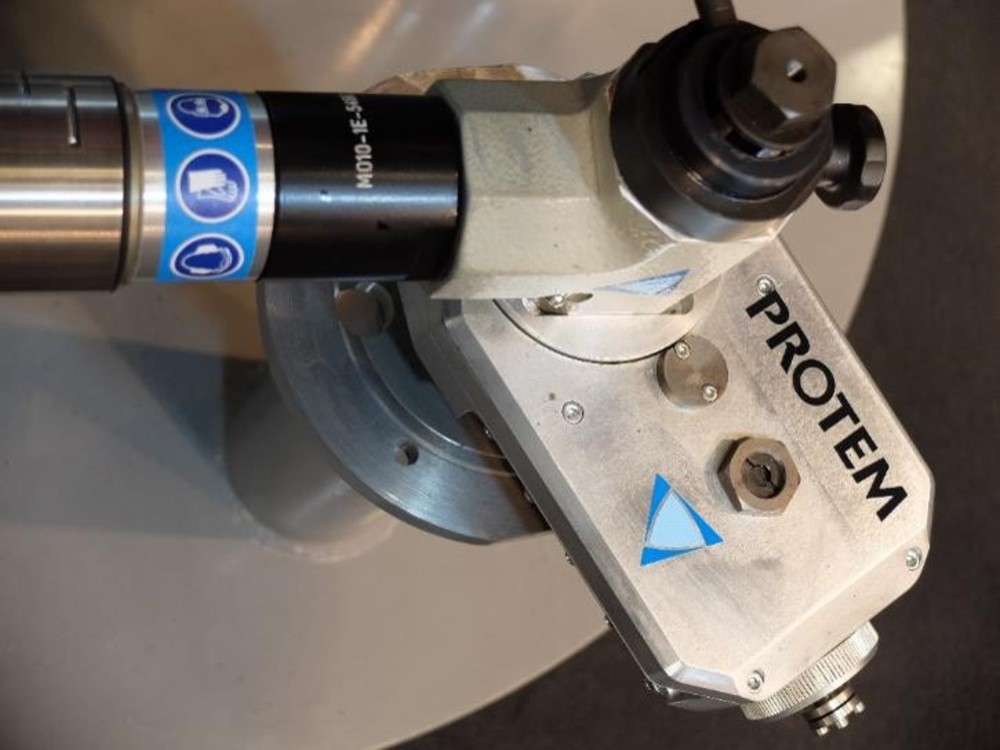

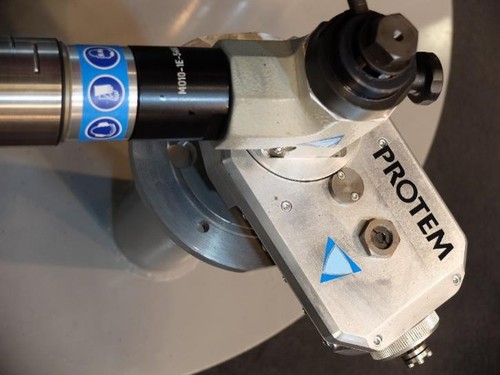

PROTEM equipment are used for the shipbuilding industry for the manufacturing and ship repair.

They cover a tube diameter range from 3 mm (0,07”) to 2235 mm (88”) as standard. Possibility to go up to 4267 mm (168”) on demand.

Our core values

- QUALITY: We know that the weld preparation quality is essential for a good weld

- FIABILITY AND ROBUSTNESS : Our customers work in demanding environment ( nuclear industry, offshore ... ) where the equipment has to be reliable.

- CAPACITY: Our customers need equipment which are able to cover all their range of diameters, wall thicknesses, materials, production rates, …

- REACTIVITY: Because our customers need quick and relevant answers along with a perfect service

- DEADLINE AND REQUIREMENTS COMPLIANCE: We are entrusted with the most important and crucial projects of our customers and we are acting accordingly

- SAFETY: We are concerned about the safety of the workers and so we design our equipment according to this principle

Our Customers in the shipbuilding industry

Some applications of Protem equipment in the shipbuilding industry

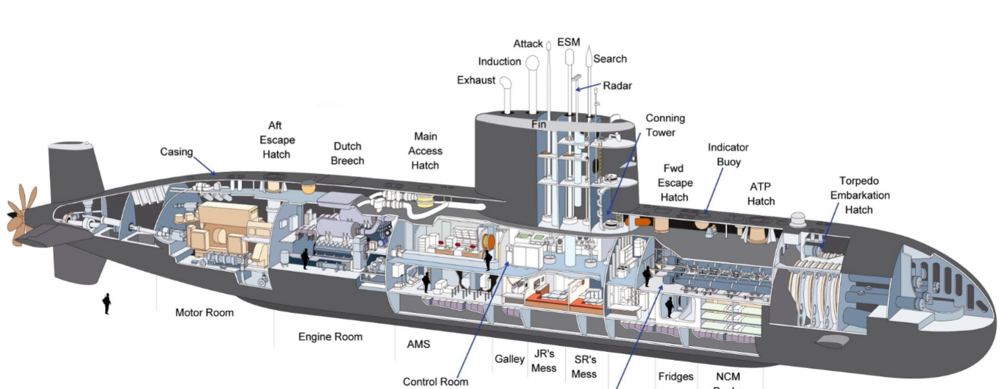

Tubes Machining prior to welding small diameter tubes in tight spaces ( submarines, machine rooms …)

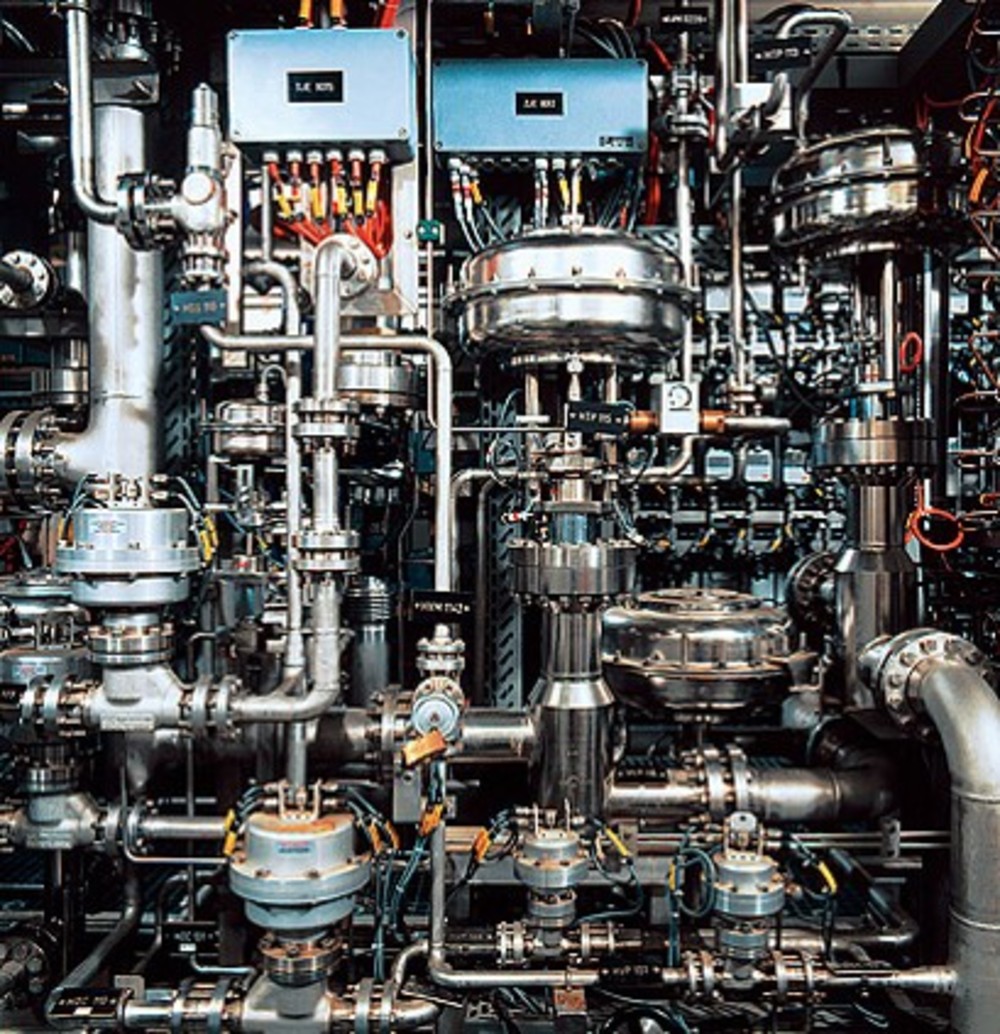

Diesel motors on-site Repair

SERCO TU – TA machines are used in the repair of diesel motors because of their boring stroke and the quality of the machining finish. It extends the duration of the life of the motor increasing savings and profits.

SERCO TU-TA machines can be used for several brands of motors. Our engineering team is also able to adapt our existing equipment to your specific needs.

Where can our machines be used ?

Special equipment Examples

Submarines : Beveling machine for submarine Hulls

Protem designed and manufactured a milling machine with an adjustable machining head which will work on the upper and lower end of the hull section.

The work to be performed is compound bevels on the inner and outer edge of a circular pressure hull section.

Thickness of section varies between 55 and 100 mm

Submarines : Automated Machine for welding submarine hulls

Protem designed and manufactured 3 automated machines using a MIG/NARROW GAP welding heads (10 mm gap. 100mm deep).

The weld is performed in two simultaneous passes though diametrically opposed welding heads in multiple passes using an oscillating wire feeder.

Weld fusion problems are eliminated.

High quality welds are achieved in both vertical and horizontal position.

The work to be performed is to weld thick plates ( 120 mm) using MIG/NARROW GAP process (horizontal and vertical).